C2 PROJECT

C2 Photo Album

album:November 2018

Major changes to the track layout at the back of Glan-y-Mor yard are taking place this month. Rail access to our shed is temporarily impossible!

A closer look at the newly prepared trackbed and some new sets of points. These will feed the new 4-road carriage shed to be built on the reclaimed land to the right.

Some features of the boiler cannot be inspected directly. Here Paul is looking through the blowdown valve aperture, and using a dentist's mirror to inspect a nearby stay.

With one of the superheater flues removed, we can look through the firebox tubeplate at the surrounding tube nest. Some of the flues and tubes seem to have been welded up from shorter sections. All these will be replaced during the boiler overhaul.

One of the small tubes has also been replaced, permitting this view along the bottom of the boiler barrel. The hole in the bottom is an access hatch for cleaning.

One of the valve chest front covers had been damaged in a collision at some stage. Erle has rectified the important interfaces, including skimming the back on a lathe, removing a bent stud in the middle and re-tapping its hole.

A stack of roller bearing cover plates from the coupling and connecting rods. Some of these can be re-used but others are badly worn and will need to be replaced. Dave has spent a lot of time measuring and drawing these, complementing Erle's work on the rods themselves.

These spigots will form part of the tender brake stretchers; they are to a similar design to those on the loco. Colin machined them up.

We've been doing a lot of work on the cylinders recently, and our activities are spreading to those components which are attached to the cylinders. This is a bracket for the draincock linkage. Very unusually, it's covered in number stampings, which probably means it's not a Chinese part but an older Polish or Hungarian one. The equivalent part for the other side of the loco has no numbers.

This is one of the old tender brake stretchers, reclaimed and machined to take new stainless steel spigots. Erle milled out the slots to fit Colin's spigots. Unfortunately the other two stretchers seem to be made of a strange alloy which is very difficult to machine!

This is where the driver's side cylinder mounts onto the frames. Chris spent a morning carefully finding high spots and paint lumps, and rubbing them down to achieve a smooth face.

Paul 2 joined us for one day of the working party, and took on the task of cleaning up a bracket that mounts onto the cylinder. This was fairly roughly made, and rather rusty. Here Paul grinds the flame-cut edges to a smooth finish.

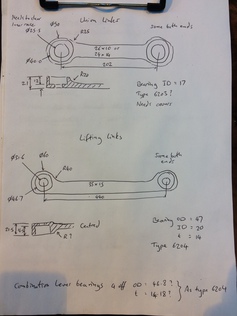

For some parts of the valve gear, we have no manufacturing drawings. The Chinese changed the design to suit roller bearings but we only have drawings of about 60% of the parts. Reverse-engineering the remainder requires careful measurement of the parts we have, comparison with the Polish and Czech plain-bearing versions, and identifying the parts they interface with. Then we can create a CAD drawing with the correct dimensions and tolerances. This is one stage of the process - a sketch drawing.

Paul 2's bracket completed and with a coat of primer.

The old reverser weighshaft was too long, now that we have re-gauged the loco. The weighstaft is easily replaced, but we wanted to re-use the cranks fitted to each end. Dave 2 cleaned up the assembly, and cut the ends off. Dave 2 and Colin then drilled out most of the stubs of the shafts, and used the press to push out the remainder. A final clean up and a lick of primer, and these parts are ready to be re-used.

These rods connect the return cranks to the expansion link. We have four, but only need two of them. Erle cleaned them up and measured them carefully, to find that they're not all the same. The longest one is more than 6mm longer than the shortest one! These have a big influence on the valve timing...

Draincock linkage brackets, now cleaned up and with a lick of primer.

Chris has been thinking hard about how to machine the new rod bearing cover plates. They're difficult to hold securely in a chuck, so has started making a fixture to clamp them during turning operations. This is the progress so far.